Summary

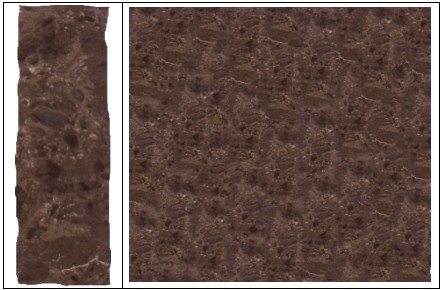

Altinex developed a process that enables close matching of any surface type colors and patterns to table top products. The only thing needed to match the surface pattern is a high resolution image of the surface or a small sample of the surface.

When a small piece of the counter-top material is provided, it is used to create the final artwork that would be placed on the bezel. This magic happened in the artwork department and, once completed, the high resolution image closely matched the pattern texture of the original material.

Once the artwork was ready, the high resolution image is applied to the surface of the bezel and color matched closely to the original sample provided by the customer.

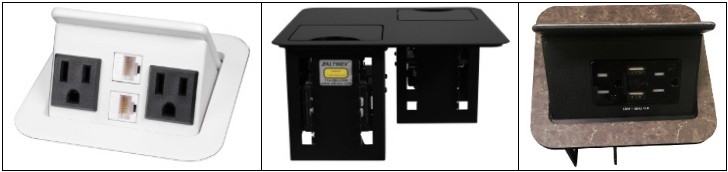

Finally, all of the units are built and delivered to the customer for a flawless installation at the customer’s location.

Notice that when units are closed, they match the surface of the counter so well that it is difficult to notice that there are actually three units installed on this counter-top.

The process of adding any type of image pattern to the bezel enables us to custom match any surface for a flawless and, in many cases, invisible installation. When combining this capability with the UL rating for kitchen and bar counter-tops, the design possibilities become endless.

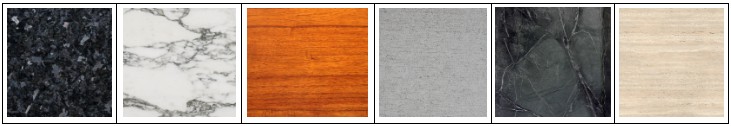

Counter-top surfaces made from granite, marble, wood, concrete, soapstone, travertine, and many more can be custom matched to your exact specification.

In addition to the custom surface matching, other images can be added that represent your unique style and personal expression. Just tell us what you want to see and we will take care of the artwork and deliver a product that will meet your exact surface specifications.

Every Custom Match unit’s surface is sealed with a scratch resistant epoxy polymer that is impervious to spills and typical counter-top contamination.

With the new Custom Match process, Altinex can address any of your custom installation needs. Give us a call and see how we can help you with your next custom installation.